Aerospace

Airbag Design For Aircraft Store Capture

Our customers seem to like working with us and we have been asked to write about what we do to make more people aware of the nature of what Simpact offer. We’d like to do this by talking about an interesting Aerospace project. Like most of our customer enquiries, it started with a phone call where we helped them to identify their requirements

“Could you drop test a fire extinguisher with your equipment?”

“Yes. What drop height and orientation? Also, what would you like to measure?”

Although it is nice when we have clients that contact us with a clear description of their engineering requirement(s), this is often not the case as it is usually them seeing how we take the first step in working together in solving a much bigger challenge.

“It might not be a fire extinguisher; it might also be a lot longer with a pointy nose…”

We really like this stage in the relationship and getting to know our new clients. It’s where the value for both parties is built and when the chemistry happens between our engineers, this is when projects really fly, especially when you get on well and share a good sense of humour. We could not help referring to Fawlty Towers, the British television sitcom from the 1970s. In particular, the episode when they had a fire drill and poor Manuel got locked in the kitchen with a real fire!

Understanding our customers requirement

Our customer had a simple but challenging requirement. They needed to test in a realistic environment, the release of a live item that is usually connected to the wing of an aircraft. This needed to be done in a safe way and historically, this test was carried out by releasing the item from under the wing into a large hole dug at the side of the runway. The hole was filled with cardboard boxes that captured the item in a progressive way. Cardboard is a cheap and effective energy absorber.

In 2012 a skydiver called Gary Connery became the first person to land safely without deploying his parachute. With his wingsuit putting him on a diagonal trajectory with the ground, he crashed through a large prismatic assembly of 18,600 cardboard boxes. Imagine the noise that would have made – like when you are slowing down over rumble strips on a fast dual carriageway!

There are known issues with this method of capture and energy absorption. For one, the weather can quickly change the structural response. When these items are released from the aircraft, the aircraft is travelling at speed, often supersonic. Our customer wanted to test the release of the item on the exit of their supersonic wind tunnel, that way, the release would be as realistic as it could be and so the solution needed to be built around the back of this facility.

Ironically and before we got involved, our customer had been drop testing fire extinguishers. From a height onto stacks of foam to get a feel for the effectiveness of this material as a concept for capturing and absorbing impact energy. Foam is a good candidate, but the energy curve is largely elastic, so you must manage the rebound, which is the energy left in the system when the foam is fully compressed and ‘bottoms out’. This could generate a problem as the stored energy in the foam item can quickly create a reverse in velocity, returning the item in the direction that it came from. We needed a capture system that would sit under the release mechanism and the supersonic airflow. One that would comfortably catch the item in a controlled way.

Once that we understood the product operational requirments, we followed the process that we employ for all our engineering consultancy projects, honed from years of automotive consultancy.

Concept Design

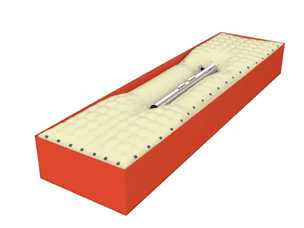

We quickly identified and recommended the use of an airbag as a proposed concept solution. For a team with many years of automotive safety experience, this was a well-known concept which we could engineer and deliver. It requires a large bag/inflated volume to capture the item after it has fallen through the supersonic airflow. The external surface and protruding components are well protected by a low-pressure airbag and once the item starts to load the system, the vents open and do the work in managing the deflation of the airbag over a specified time period. The item comes to rest at the base of the airbag which contains a foam padding. After explaining the merits of a contained, portable reusable system like this, our proposal to design, develop, build and test the system was agreed.

The system needed to be delivered as a working prototype to the site of the confirmation test and so the airbag system was integrated into a containment box compatible with the test setup, with wheels that can be deployed for positioning. The image below shows a simple rendering of the airbag capture concept.

Design Development

For the development of the design, we started by investigating what we required for the foam padding. We designed a set of experiments where we drop tested a steel ball bearing onto foam samples using our SDR 2200 drop test facility. By tracking the displacement of the ball in the context of the full-scale item, it was possible to derive the best foam characteristics.

To build an understanding of the full-scale airbag system, we designed and manufactured a small-scale representation of the airbag concept with a design that could be easily replicated experimentally. Our high-speed camera and instrumentation provided us with the data that we needed for us to correlate our numerical model.

Full Scale Dummy Item

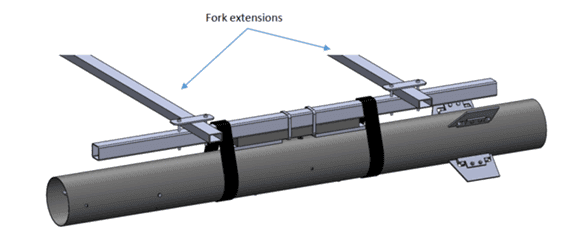

For the drop test evaluation of the full-size item at Simpact, we required a simple dummy representation of the actual drop item. We designed and manufactured this so that it had the same external geometry and centre of gravity. The simplicity of this design allowed for the safe internal mounting of our instrumentation which was two linear accelerometers.

The drop test facility is set up in our main workshop making use of our SFR 6300 which is a bespoke free-fall rig suitable for the drop testing of heavy objects up to 350kg at a height of up to 6.3m.

An electromagnet release mechanism provides a clean and remote release of the dummy item at the desired height. The head of the rig can be adjusted to give various angles, and fork extensions give us the required reach over the airbag system. For safety, two heavy duty Velcro band straps are removed once the drop test is ready.

The developed finite element model of the airbag system which includes pressurised airbag, vent holes and tethers is used to tune the design of the system. It is then used for a design of experiments (DOE) where a multitude of drop scenarios are investigated, including drop location and drop angle. The behaviour and acceleration of the item are investigated and any failures to capture the item are noted / confirmed as unlikely in test.

The DOE are successful in highlighting the system’s strengths, weaknesses and sensitivity, and modifications to the design were considered to increase its effectiveness in the most relevant scenarios. The final design of the system is confirmed where the final performance is basically a trade-off between drop position/angle, minimum/maximum allowable drop height and acceptable rebound.

Verification Testing and Customer Delivery

System as built worked as intended. The results and the data collected from our full scale drop tests (high speed video, acceleration-time histories and pressure-time histories) matched our model predictions well and confirmed that the design changes suggested by the modelling worked to our advantage.

Our customer witnessed the testing and was pleased that the project went well. Delivery of the system was successful and put them in good shape for the live test which was done as planned at the back of the wind tunnel. As it was a live test, the test was carried out by personnel remotely at a safe distance.

Download the Case Study

Simpact_On_Fire_R4_FINAL.pdf

Get in touch

We would love to hear about your project, get in touch and let’s explore how the expert team at Simpact can take it from design target specification through to verification.