Consumer

Bicycle Helmet Impact Development for EN1078 Drop Test Certification

Our customer was an Industrial Design Consultancy who were working closely with a new manufacturer of a range of road bicycle accessories.

The Helmet and Loadcases

Our customer is an industrial design consultancy providing new product innovations for a wide range of clients for more than two decades. Their bicycle accessory customer had developed the concept of a road cycling helmet with integrated streaming camera technology. The smart helmet records and shares cycling activities and the integrated design incorporates image controls, chipboard and battery. The front facing camera system adds only 0.1kg to the helmet which also includes a licenced MIPS (Multidirectional Impact Protection System).

EN 1078 is the European safety standard for bicycle, skateboard and roller-skate helmets. The experimental drop test evaluates how well a helmet reduces head acceleration during a collision. The standard defines the headform, impact points, drop height, anvils and the maximum allowed accelerations.

The helmet is dropped in a guided fall much like our inhouse drop rig which guides the headform so that it hits the anvil(s) correctly. The image on the left shows the relevant loadcases.

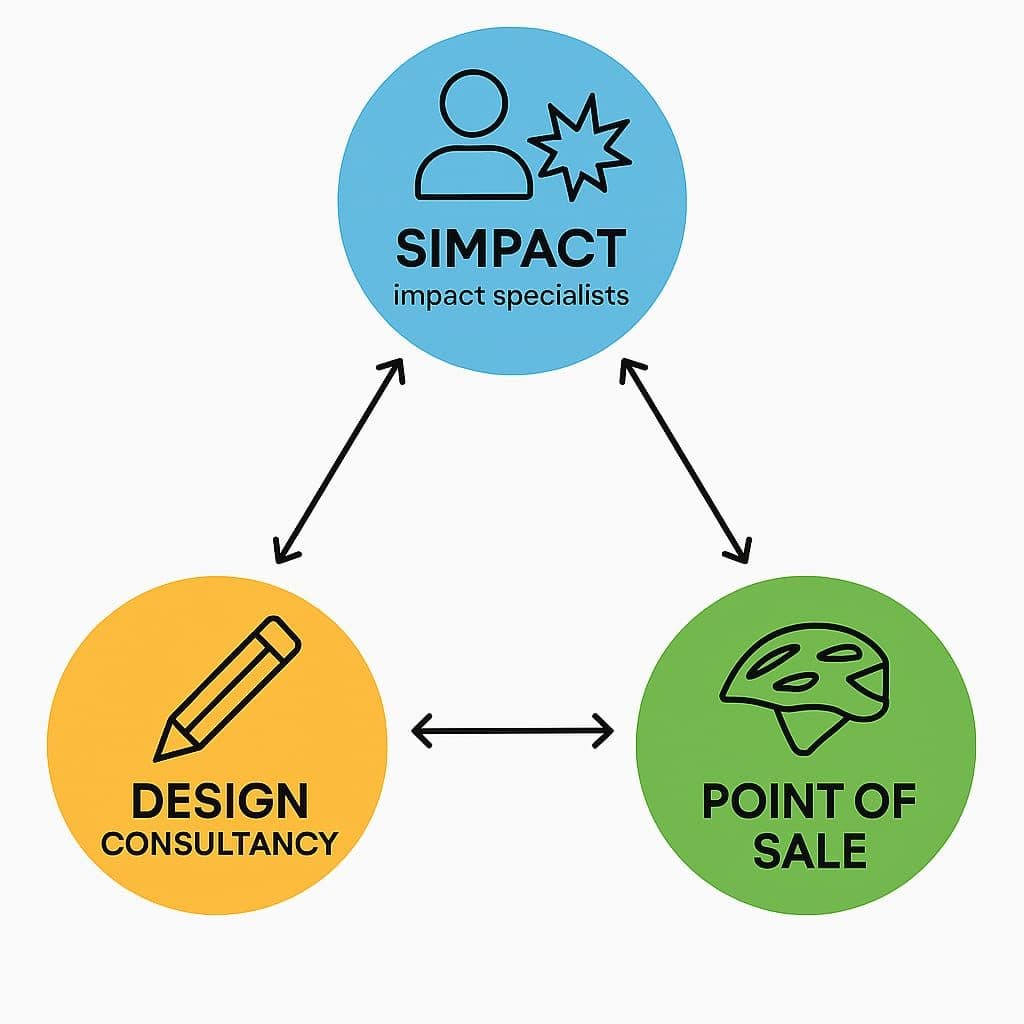

Working seamlessly within a trilateral partnership

We have a great deal of experience working within a trilateral partnership which is entirely complimentary. The design consultancy already have the contract for the design and development of the prototype and have called on our support for Mechanical Engineering advice and impact design/development where required.

There are several ways in which a partnership is formed. Many of our partners are returning clients as they experience the success of working with us before. These same clients also act as ambassadors sharing their story. Then there are also new clients that come across articles like the one in front of you. Our charges are milestone linked. This helps in securing new clients as they can experience the value first hand before committing to a full programme.

All of the work was done remotely using Teams with the customer (point of sale) outside of the UK.

CAE Model

For the headform, we made use of a Hybrid 3 Anthropomorphic crash test dummy head which was modified to EN960 headform size and to suit the standard and fit the helmet – this has a tri-axial accelerometer. The flat and kerbstone anvils are as per the standard and assume steel material properties.

For the helmet assembly, we built a detailed finite element model using a combination of solid and shell elements. This included accurate geometric representation of the structural inserts and outer shell. For the other components including the camera, camera casing and battery, we took a sensible approach where we used a relatively simple description that gives a conservative impact performance. The mass of each component is checked against the BOM. (Bill of Materials)

Calculations were carried out using the RADIOSS CRASH explicit non-linear FEA software as this is well suited to the materials and loadcases under investigation. The matrix of loadcases and small element sizes required to capture the geometry drive a small timestep for the calculations. The large deformations in the EPS foam inevitably result in numerical instabilities for this type of analysis and so the onus is on producing a good quality mesh of the main load bearing components.

Materials Characterisation

Initial runs confirmed that the EPS foam is by far the largest contributor to overall energy absorption. Although a literature search identified a paper presenting detailed compressive properties of EPS foam, these properties were confirmed to match the actual foam used in the helmet by generating samples and tested them dynamically in our in-house drop test facility. The experiments included instrumentation, specifically our high speed camera, force platform and accelerometer. This data was successfully captured, replicated and correlated with numerical analyses making use of the derived material model.

Initial runs also highlighted a vulnerability where the kerbstone anvil can wedge its way into the vent holes of the helmet resulting in tensile load. The above dynamic compression testing was further complimented by quasi-static tensile tests carried our using an Instron tensile test machine. These additional tests allowed for the inclusion of a failure criterion based on the maximum allowable tensile strain.

Results, Design Iterations & Conclusions

Eight loadcases were analysed that covered the agreed impact positions where the helmet contacts the flat and kerbstone anvils. The calculations were carried out in two phases which allowed for a CAD update on completion of the first phase of work. We like to work on a simple traffic light system with our customers which correspond to a likely pass (green), a warning (amber) and a fail (red) reporting style. This system clearly identifies issues that require addressing and at the same time, we identify areas where there is a safe margin of acceleration and total compression. This can lead to a lighter design and the CAD model is updated with our design concept recommendations for Phase 2.

Sensitivity analyses were carried out. For example, the ABS skin that protects the EPS foam reduced the tensile loads and this led to a decision on the best skin thickness. On completion of Phase 2 and a predicted pass of all loadcases, the design is finalised in CAD and the helmet manufacturer has the confidence to commit to tooling investment. Once manufactured to the design specification, the first serial production prototype is ready to demonstrate a clear pass of the EN 1078 certification test requirement.

Get in touch

We would love to hear about your project, get in touch and let’s explore how the expert team at Simpact can take it from design target specification through to verification.