Automotive

BLiSS - Butted Lightweight Steel Structures

The BLiSS project delivered the worlds first double-butted automotive spaceframe

The UK low volume/niche vehicle industry and the bicycle industry have been a particular interest of ours and in this project, we transfer technology from one to the other and evaluated the use of butted (variable wall thickness) tubing for lightweight automotive spaceframes.

Project Partners

Working closely with project partners Reynolds Technology and Caterham Cars Ltd, the project was part funded by the UK Niche Vehicle Network (NVN) and their Proof of Concept Competition. Reynolds are well known for inventing the tube butting process in 1898 and their lightweight, high strength tubing is used predominantly in the bicycle industry. Caterham Cars make the iconic Super 7 sportscar and as power to weight ratio is a key performance measure in their market, there was a strong interest from our niche automotive partner who we knew well having a long history with the development of the Caterham 7 - in particularly safety and crash test development.

Simpact was responsible for creating a simulation driven process using FEA tools that incorporated up-to-date CAD information from Caterham and KPI's derived by Simpact

Design Target Specifications

The project would investigate the weight saving potential based on a benchmark Caterham Series 3 chassis.

Senior engineers at Caterham were very clear from the start that they were only interested in maintaining the torsional stiffness of the 7. There is a clear logic here as the stiffness of the car was known and the suspension tuned for compatibility.

Equally of importance was to ensure that the existing chassis production was not effected. So that included all of the jigs for spaceframe manufacturing. Vehicle packaging should also be kept unchanged.

By creating a virtual (FEA) model of the Caterham 7 and correlating the model to torsional test of the baseline S3 chassis, the model can then be used as a tool to determine which tubes should be replaced with Reynolds tubing. Reynolds identified all options on materials, typical yield strength, tube sizes and dimensions possible.

It should be noted that in a perfect spaceframe, the linkages that connect the nodes are only loaded in tension or compression. From a stiffness point of view there would be no advantage in using butted tubing. However, in the S3 chassis triangulation is not perfect and consequently several tubes are loaded in bending. Therefore, with the bending moments being highest at the tube ends butted tubing gives an advantage.

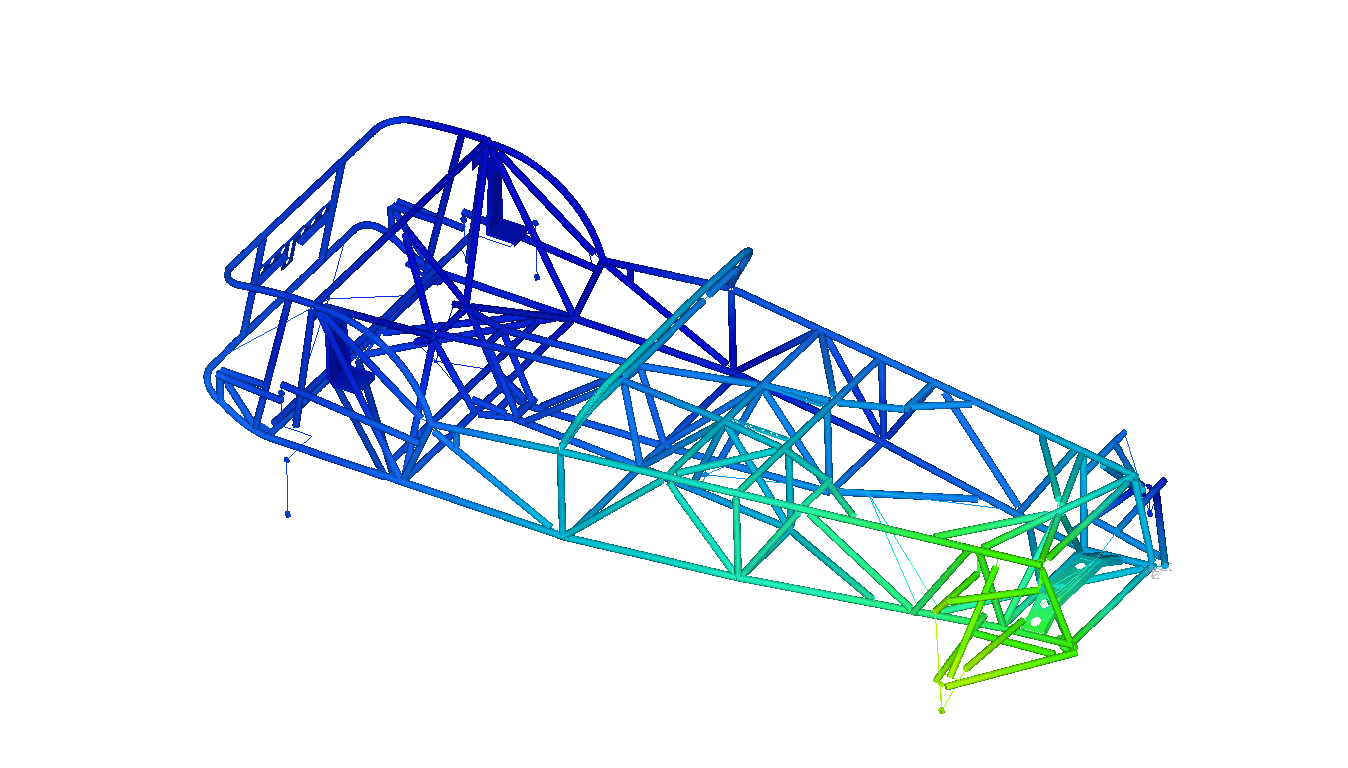

Concept Design & Analysis - Beam Element Model

A simple beam element model is well suited for the modelling of a thin walled tubular spaceframe like this. Especially during the early concept design phase of the project where quick run times and investigations are required. The beam element formulation represents the prismatic cross section perfectly and the model can be constructed quickly from the Caterham CAD model.

The front and rear suspension including rear de-Dion tube are added to the model so that the torsion load case can be applied in precisely the same way in which the car is loaded from the road.

Tube components subject to bending are quickly identified by the beam element model and we work closely with Reynolds to provide a proposed specification for tube substitution.

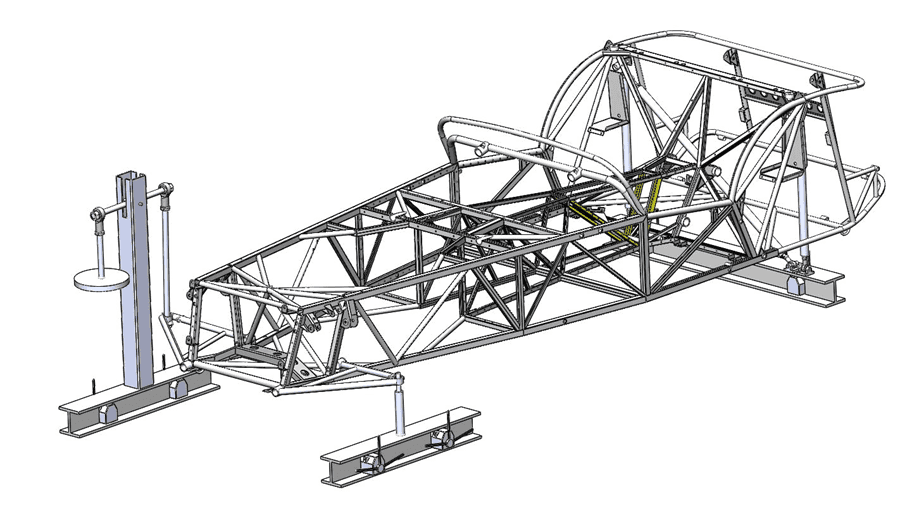

Torsion Test Rig Design & Verification

A universal torsion test rig was designed in CAD and manufactured by our local fabrication and machining partner. The rig is designed to asses the main KPI for the project which is torsional stiffness. The design included magnetic clamps which firmly secure the rig to a flat metallic surface as the plan was to make use of the large CMM at WMG at the University of Warwick for the testing. Here we tested the bare Caterham 7 spaceframe, another with aluminium panelling and a selection of roll cages so that we could quantify the effect of the panelling and roll cages on torsional stiffness.

The beam element model is correlated to within 5% of the test data.

Detailed Design & Analysis - Shell Element Model

The beam element model was developed into a fully detailed shell element model so that the detail of all of the the joints in the spaceframe and the aluminium panelling/bodywork and front and rear suspension could be included. The investment in this very detailed and impressive FEA model meant that it could be used for a variety of other loadcases such as durability and crash.

By including this level of detail the model was correlated to within 3.3% stiffness of the baseline. The model was then used to refine and confirm the package of butted tube substitutions for Reynolds to manufacture.

Prototype Spaceframes

Completion of the project resulted in two proof of concept series 3 vehicle spaceframe prototypes. Manufactured by their chassis supplier, one was sent to Simpact for torsion testing (REY001) and the other was built into a complete vehicle (REY002). Resulting in the worlds’ first butted steel spaceframe, the weight reduction compared to the original benchmark spaceframe exceeded 10%, whilst maintaining the original chassis torsional stiffness.

Existing chassis production was not effected where the spaceframe jigs, as well as vehicle packaging was kept unchanged. The added-on cost for introducing the technology was kept within 20%.

Road testing of REY002 and subjective driver feedback collected by Caterham stated an improved power-to-weight whilst maintaining of handling key performance.

Get in touch

We would love to hear about your project, get in touch and let’s explore how the expert team at Simpact can take it from design target specification through to verification.