Defence

How soft armour works

Have you ever wondered how a bullet resistant jacket works and how the layers of fabric within stops a bullet? Simpact have, and by understanding fully how something works you are in a much better position to tailor a better solution towards a specific set of requirements. It makes the difference between a trial and error and a scientific approach.

What is the threat?

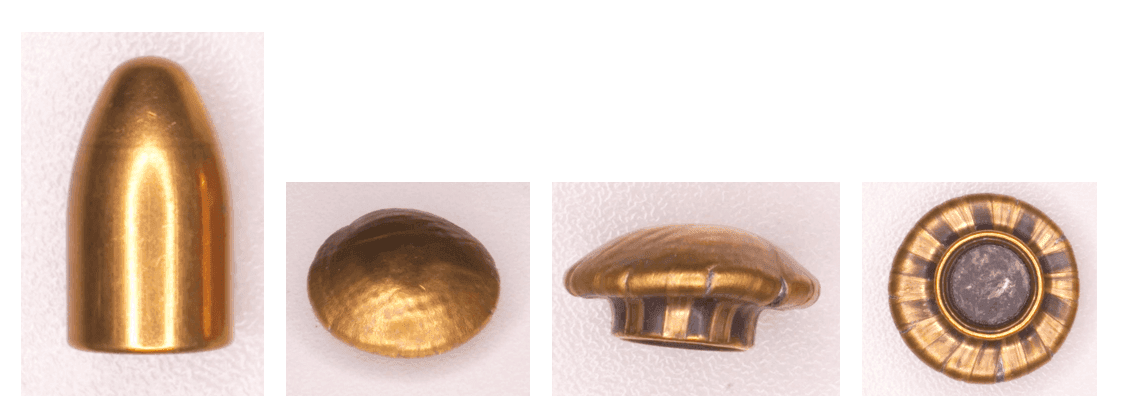

The process started with close inspection of the components involved. First of all, there is the threat that you need to defeat. There are many different threats to consider but for this type of equipment, our initial focus was on the 9mm DM11A1B2 bullet. This type of bullet is commonly used in hand guns by law enforcement personnel. It is a round nosed lead filled projectile with a copper coated full steel jacket.

When defeated by impact with a soft armour, i.e. layers of fabric, it has changed into a mushroom shape. Notice the front face of the bullet head where you can see the imprint from the texture of the fabric. In the rear view of the mushroomed bullet, you can clearly see the lead core and the markings from the rifling of the gun barrel.

Aramid as a soft armour

Typically, soft armour consists of several stacked layers of woven fabric, ten or more. Here we focus on woven Aramid fabric. The layers can be held together by quilting and are contained in a sleeve to form what is referred to as a 'firing pack'. Aramid fibres are quite slippery and the woven fabric frays easily.

When a firing pack is shot, often several layers from the front of the amour pack are penetrated up to the layer that arrests the projectile.

Quantifying the Phenomena

You can observe several phenomena that occur, each contributing to the dissipation of the kinetic energy of the projectile. There are:

- Stretching and ultimately rupturing of the filaments in the yarns of the fabric

- Individual yarns slipping within the fabric

- Bunching of yarns around the impact point

- Slipping of fabric sheets over each other

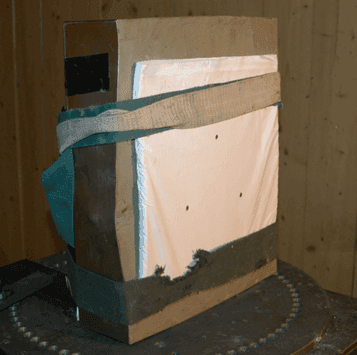

- The bullet head changing shape

To quantify the energies involved in each of these phenomena by just looking at the final static state of bullet and firing pack is not straight forward. A common technique to learn more about the performance of a specific armour solution is to carry out ballistic tests in a controlled environment. It requires constraining the firing pack. In personal protection applications (PPE) the armour is worn on the body. To mimic the compliance in the body, the firing pack is placed on Roma Plastilina. The indentation that a bullet impact leaves in the Plastilina is an indicator for the risk of blunt trauma injuries.

To eliminate the variability that the Plastilina introduces an alternative constraint in the form of a ring frame is used. It is less representative for PPE but still allows comparison between different firing packs. Although this approach eliminates variability in the Plastilina, it introduces variability in slip of the pack in the frame. High speed video and laser technology can be used to measure dynamic displacements but only of exposed surfaces.

Some well-known in the armour industry did give up at this point and resorted to saying what happens is art that cannot be unravelled. Being engineers we didn’t let this limitation stop us in our quest to understand exactly how soft armour works. This was over two decades ago.

Our propriety FEA models give the answers

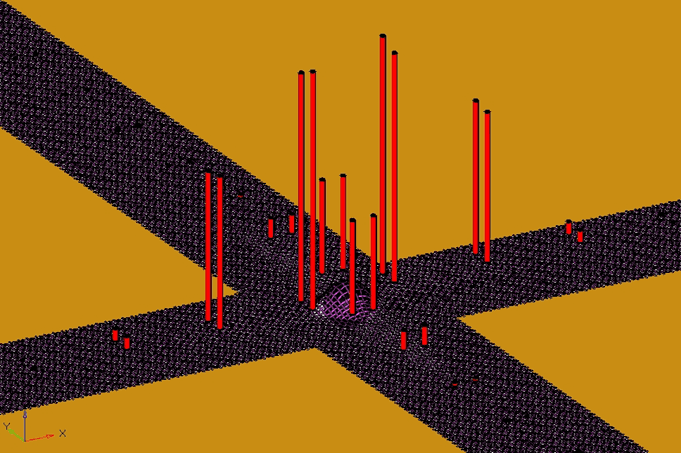

We characterised the material mechanical properties up to the relevant strain rates, captured the geometries in the system, determined friction properties. We then created non-linear explicit finite element models including SPH that we validated against experimental test data first at component and then at system level.

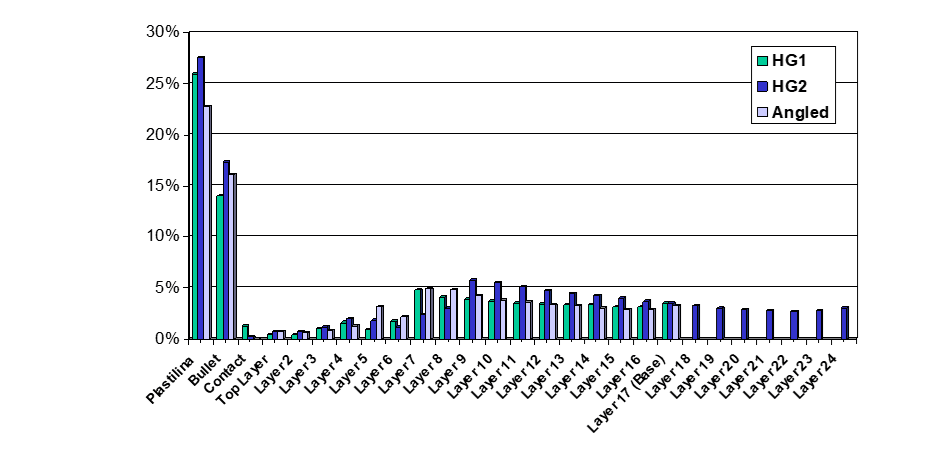

Our proprietary FEA models gave us the answers. This ranges from global behaviour all the way down to yarn level. Globally, the distribution of the kinetic energy into areas such as deformation of the Plastilina, the bullet, friction between the sheets of fabric and the sheets themselves.

The models give us the understanding how soft armour works. They allow us to identify the limiting factors of the design and give direction in the search for improvements.

Get in touch

We would love to hear about your project, get in touch and let’s explore how the expert team at Simpact can take it from design target specification through to verification.