Defence

Shaping the Future of Body Armour

The effectiveness of PPE is compromised by ergonomic issues hindering the wearer's mobility. This study describes what it takes to develop more ergonomic chest plates.

The Chest Plate Dilemma

The perceived comfort level of hard plates used as ballistic armour affects the mission effectiveness of the wearer; however, due to manufacturing challenges and lack of clear ergonomic requirements in the current standards, most plates are relatively flat and uncomfortable as they are not based on a realistic torso shape.

In our publication ‘Why is my rifle plate so uncomfortable?’ which was presented at the Personal Armour System Symposium (PASS), Amsterdam 2016, we detailed the efforts of the Metropolitan Police Service to define the ideal shape for a wide range of police officers.

This R&D produced a prototype chest plate which became the basis for a new generation of ergonomic armour. With a deep 3D geometry much like a torso, the challenge then lay in how to press such a geometry.

With part funding from Innovate UK and project partner WMG at the University of Warwick, Simpact have developed COMPPRESS; a new in-house composites manufacturing facility that can produce deep 3D polyethylene (UHMWPE such as DSM – Dyneema®, Honeywell – Spectra®, FMS) based armour systems using rapid low cost tooling.

This Case Study summarises the steps that Simpact took to create an ergonomic chest plate design which was then manufactured by COMPPRESS using the DSM Dyneema® UHMWPE material to create the functional chest plate prototype. This demonstrator is now helping to open up opportunities for a new generation of ergonomic body armour.

Modern Chest Plates

Modern rifle-resistant chest plates either fit in an existing body armour system (usually in conjunction with a soft body armour jacket) or are stand-alone. Most chest plates currently in production have a relatively flat (Small Arms Protective Insert) ‘SAPI’ style shape and are not regarded as comfortable.

Manufacture of these plates in UHMWPE requires large high capacity presses with expensive metallic tooling. Tooling investment and the challenges associated with the deep 3D geometry of ergonomic armour are preventing progress in the armour industry.

Body Scanning of MPS firearms officers

45 police officers, of which 7 were female, were scanned at the MPSTC (Metropolitan Police Service Training Centre), Gravesend. By splitting the officers into 6 groups standing in a circle, we captured complete torso geometries in 3D using a FARO Focus3D X 330 laser scanner (shown in the centre of the group). Although it’s a long range, large volume scanner typically used to capture large datasets in the construction industry, we developed a technique to rapidly acquire body shapes of multiple test subjects.

The officers wore special tight-fitting tops which registered the sensitive laser well and exposed the chest shape. The figure on the left is a comparison between a scan of a naked torso and the same torso with the tight-fitting top. The compressed areas are shown in blue, while in red it is possible to see the areas of the top that stand slightly proud of the body. The resulting scanned surface, while still closely following the body shape, has a slight interference with the pectoral muscles and no direct contact with the sternum: these characteristics can lead to a chest plate which spreads most of the load on the compliant tissues, preventing any hard, uncomfortable contact with the bones.

Analysis

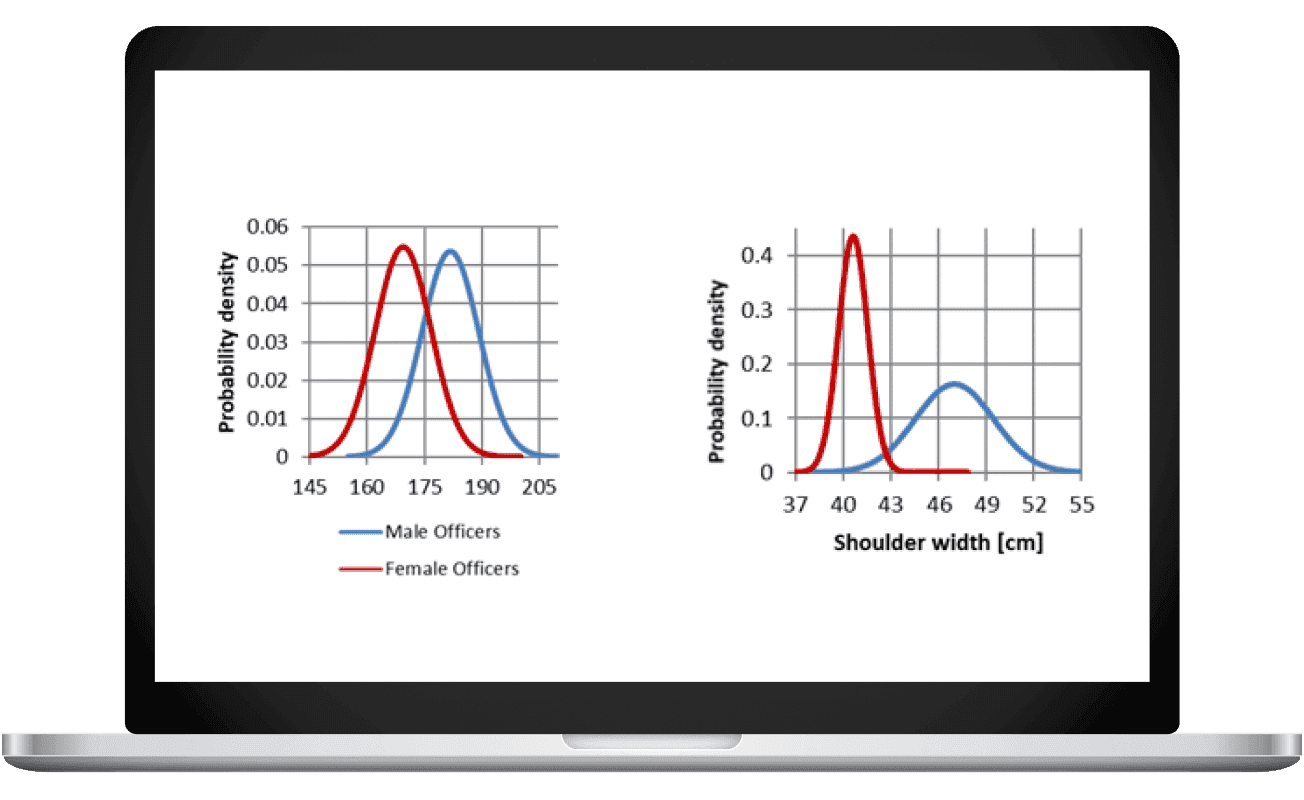

The average height of the analysed population was 182 cm for males and 170 cm for females. A similar standard deviation is observed for both groups. Since the height of the torso is roughly proportional to the overall height of a person, this data was useful.

Shoulder width is another indicator of build type and the average shoulder width in the population was 47 cm for males and 41 cm for females. A much wider spread was observed in the male population likely due to the higher variability in muscular mass in males, as opposed to females.

The ratio between height and width is another indicator of the build type of an individual. The average ratio was 3.87 for males and 4.17 for females.

3D Printing of Prototype Plate

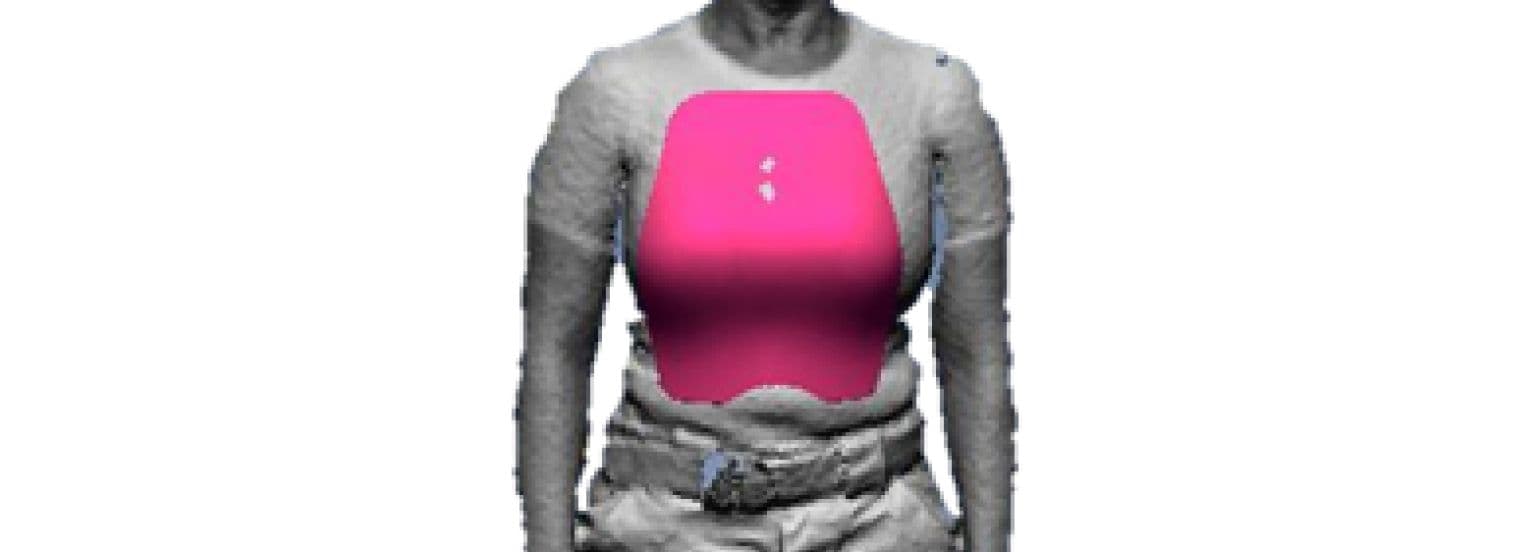

A male chest plate was derived in CAD from body scan point cloud data. The outline that was derived provided maximum coverage, while still allowing normal movements of the torso and arms. The resulting CAD model was sent for 3D printing in a 3mm black ABS polymer. The thickness was chosen to make the ergonomic demonstrator suitably stiff, while minimising material costs.

Ergonomic Assessment

The male officers scanned at the MPSTC were asked to wear the 3D printed prototype ergonomic chest plate to evaluate shape and fit. The officers were asked to stand and assume a typical handgun shooting position to assess the required clearance between the arms.

The ergonomic chest plate was a good fit for 56% of the population of police officers with average chest size, with an additional 20% finding the shape in need of just minor modifications. The fit of the plate appears to be worse for officers of large and very large build. Overall, almost 65% of the tested male population gave the plate a positive score and rated it higher than the plate currently in service.

Conclusions and Further Work

The study shows that an ergonomic chest plate purposely designed to even the pressure distribution on the torso of a sample subject can provide a good fit for most of the assessed population. This proves that pressure distribution is what drives the perception of comfort when wearing a plate. A comfortable chest plate shape needs to be based on a realistic torso geometry and this conclusion will inform a new generation of ergonomic armour that will enhance the comfort and mission effectiveness of the wearer.

With some minor modifications it is believed that the next plate will fit the vast majority of police officers with athletic build types better than the current prototype plate. We have now made use of the MPSTC 3D body scan data to design and carry out new virtual ergonomic assessments trialling a new set of male and female chest plates. These have been 3D printed and are awaiting ergonomic assessment at MPSTC.

The Physical Protection Group can count on Simpact to provide high quality, impartial consultancy making use of the best methods and the latest technology to protect our police officers.

Paul Fenne

Head of Physical Protection – Metropolitan Police Service

UHMWPE Manufacturing of Ergonomic Plates using COMPPRESS

A fully functional version of the prototype ergonomic chest plate was manufactured by COMPPRESS using DSM Dyneema® UHMWPE.

The CAD model for the ergonomic chest plate was used to derive the rapid low-cost tooling which was ready within a week. The tooling provides an A-surface for the uniform consolidation and a barrier to the high-pressure environment. The high pressures (up to 200Bar) result in superior ballistic performance from the uniform consolidation and lack of voids in the ply stack.

With one week lead times and tooling costs of less than £1k, this new process of consolidating polyethylene represents a significant value proposition to our body armour clients wanting to make quick product customisation and bespoke high value protective equipment.

Get in touch

We would love to hear about your project, get in touch and let’s explore how the expert team at Simpact can take it from design target specification through to verification.