Research & Development

Simpact has always been dedicated to carrying out cutting edge R&D. Both directors have research backgrounds in subjects highly relevant to our core business and we have developed strong relationships with UK universities. As a result we are at the forefront of innovative technology, creating and developing exciting new processes and products.

Since incorporation, Simpact has carried out several in-house R&D projects, Knowledge Transfer Partnerships (KTP's) and Collaborative R&D (CR&D) projects with customers and UK universities. These have been focused on novel ideas with strong commercial outcomes. Our larger projects are generally funded by Innovate UK, the UK's innovation agency.

The unique combination of Simpact's advanced modelling capabilities and the state-of-the-art metrology and visualisation facilities at the University of Warwick is enabling us to radically improve the accuracy and communication of impact simulation. This R&D has stimulated project work with Simpact’s customer base and provided us with a platform from which we can develop and manufacture our own products.

Some of our R&D projects are summarised below.

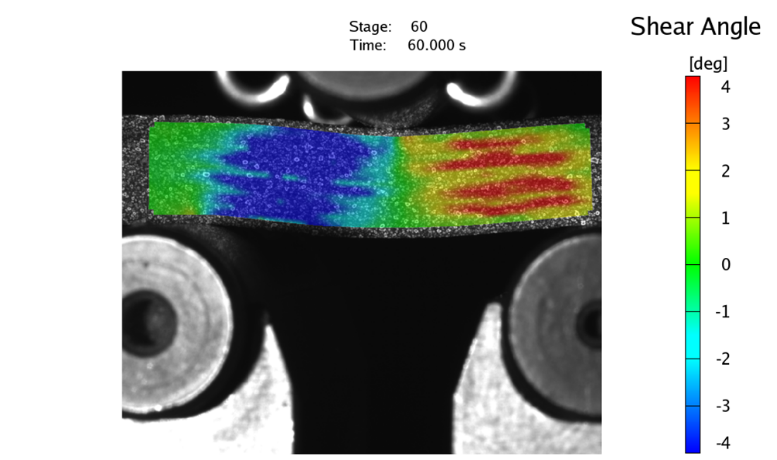

(2017-2018) COMPPRESS – An Innovative Step in the Compression Moulding of Composites

The compression moulding of composites is a new and growing sector. High quality parts with controlled surfaces, short cycle time and superior mechanical properties currently need significant capital equipment outlay (high load capacity press), tooling investment (CNC machining) and time to manufacture.

Led by Simpact and carried out in collaboration with WMG at the University of Warwick, the project investigated a completely new and highly disruptive innovation in the compression moulding of composites. Designed to open up the market for structural composites, improve productivity and market position for the UK.

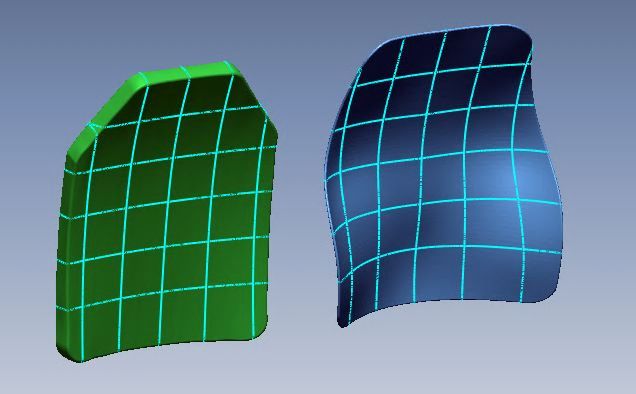

The project delivered the COMPPRESS technology demonstrator machine, now housed in Simpact’s brand new Composite Manufacturing Laboratory. To serve our defence market, it was used to produce an UHMWPE ergonomic chest plate prototype. The shape of the plate is derived from our project work with the Metropolitan Police which was presented at the PASS Personal Armour System Symposium in Amsterdam 2016. The shape is challenging to produce using conventional methods because of its extreme curvature.

(2017-2018) SPACETRAIN – Spaceframe Structures for Rail

SPACETRAIN was a 6-month Technology Transfer project part funded by the Niche Vehicle Network. Led by Simpact in collaboration with project partners Creactive Design and Reynolds Technology it successfully transferred lightweight spaceframe technology developed within the UK Niche vehicle industry into the UK rail interiors industry.

Using CAE tools and techniques developed from our automotive niche vehicle projects, we were able to rapidly assess a series of design ideas resulting in more detailed analysis and delivery of a cantilevered seat support structure at a weight saving of more than 25% of a well-known baseline fixed to the floor. The advanced design delivered superior NVH and the high-grade Reynolds butted tubing provided excellent fatigue resistance.

The project not only delivered the demonstrable output with the build of a physical demonstrator, we built a full train interior in CAD and fully rendered to create a highly realistic prototype for effective demonstration using our in-house HTC Vive VR equipment. Please see our Case Study area for more details

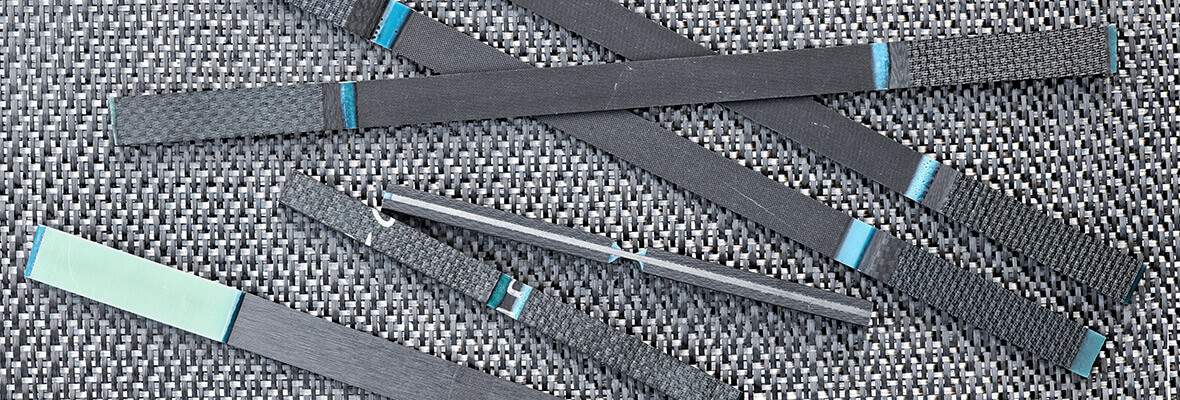

(2017-2018) LABCOMS – Lightweight Advanced Braided Composite Structures

LABCOMS was a 6-month Proof of Concept project part funded by the Niche Vehicle Network. Led by Composite Braiding with project partners Simpact and Ariel, it set out to design and manufacture a lightweight thermoplastic roll structure for the Ariel P40 Hipercar platform.

To design and manufacture a structure that met the strength and stiffness requirements including the F.I.A (Appendix J – Art. 259 static load test) in just 6 months, a CAE led approach was required. A combination of linear and non-linear solvers and element formulation were used at various stages within the project, Materials characterisation was carried out at our University partner test facility. This included tension, compression, IOSPESCU, 3 point bend and a range of bolted and bonded lap shear samples.

The project delivered a retrofittable structure that fitted the car without any adjustments at a 53% weight saving compared to the existing steel baseline design. The new structure was similar in stiffness to the baseline and exceeded the yield point of the baseline in the FIA test (and failed in a progressive manner). NVH testing at ASDEC indicated superior damping properties.

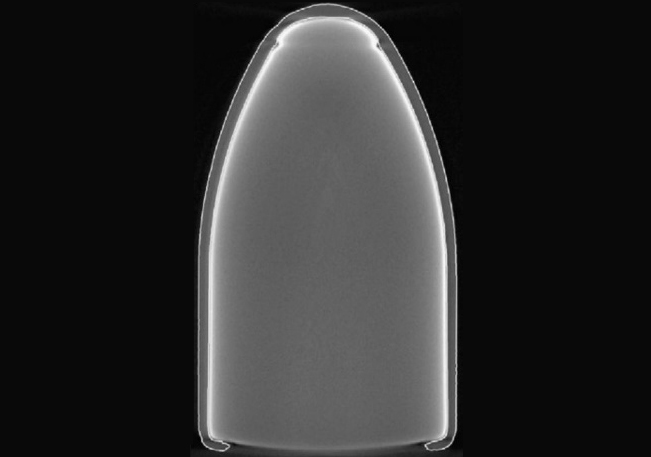

(2016) Ergonomic Chest Plate

This project set out to define an ideal chest plate shape to give the best wearability to a wide range of users. Non-contact 3D laser scanning was carried out on the torso's of 47 firearms officers at Metropolitan Police Service Training Centre (MPSTC). A high-level statistical analysis was carried out on their height and shoulder width and the data subsequently used to derive an anatomically correct chest plate geometry. The new chest plate demonstrates that a comfortable chest plate shape needs to be based on a realistic torso geometry, and confirms the suitability of the applied techniques to this project. This study thus aims to set the basis for a new generation of ergonomic armour that will enhance the comfort and mission effectiveness of the wearer.

The work was presented at PASS2016 (Amsterdam) by our project partner, the Metropolitan Police Service. Please see our Publications area for more information.

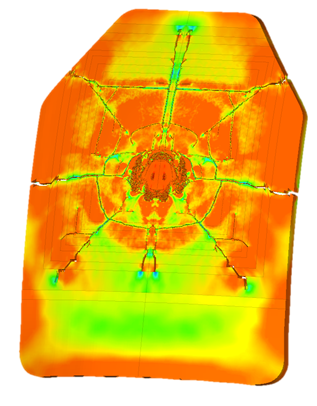

(2016) PASS2016 – Experimental-based numerical simulation of the drop test within NIJ Standard-0101.06 for personal hard armour development

Personal hard armour systems seeking certification within the NIJ Standard-0101.06 have to meet the minimum required ballistic performance after being drop tested. Passing the drop test currently involves extensive experimental testing that has to be carried out at a late stage in the armour system development, with consequently high costs and business risks. This often results in unnecessarily over-engineered plates. This work details the creation and use of a numerical tool able to accurately predict drop test performance with the Finite Element Method at a fraction of the cost and risk involved in the purely experimental approach.

Simulated drop test results from the numerical model are compared to laboratory-controlled experimental testing based on the NIJ Standard-0101.06 and successfully validated with high-speed videos, X-ray and thermal analyses. The tool has deepened our understanding of the response of the plate to drop test and is currently being used to develop a personal armour system able to meet the NIJ requirement at minimum weight and bulkiness.

This work was presented at PASS2016 (Amsterdam). Please see our Publications area for more information.

(2016) – LIFT (Lightweight Innovative Flexible Technology)

This exciting one year feasibility project saw off competition from businesses across the country in a £20m competition run by the Government’s innovation agency Innovate UK and the Office for Low Emission Vehicles. It investigated a completely new and highly disruptive lightweight automotive suspension concept and could eventually result in weight savings exceeding 150kg when applied to normal road cars.

As project lead, Simpact tested the new concepts virtually first, making use of their knowledge in advanced materials and structures to combine the necessary elasticity and damping properties with durability and wheel control within a significantly simplified system. This eliminated discrete suspension components and developed an integrated system to provide superior performance and deliver considerable weight and cost savings. With project partners, Ariel Motor Company and the University of Warwick, Simpact tested their model against real-world road and track data and was able to quickly test and validate new parts of the design. The Ariel Atom is a perfect high performance platform for demonstrating this radical innovation.

On successful completion of the project, the project partners developed the virtual prototype demonstrating the feasibility into a physical prototype.

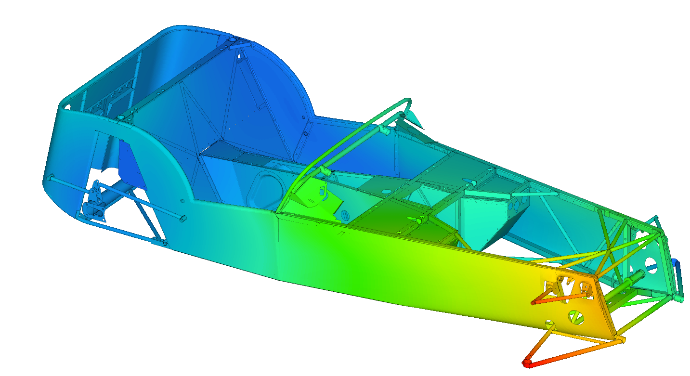

(2015) BLiSS (Butted Lightweight Innovative Steel Structures)

The use of butted tubing is better known for performance and racing bicycle frame construction. Traditionally, it is thicker at the ends than the middle, making the tubes lighter whilst retaining strength and weldability at the tube ends.

This project delivered the world’s first spaceframe chassis using butted tubing technology and Simpact will work alongside Reynolds Technology, who pioneered the original double-butted tubing set in 1898, and Caterham Cars Ltd, manufacturers of the legendary 7 sports car.

Grant support for the engineering and development project was provided by the Niche Vehicle Network, which offers innovation support to the UK’s vibrant niche and specialist vehicle manufacturing sector. The Network’s activities are funded by the UK’s innovation agency, Innovate UK, the Office for Low Emission Vehicles (OLEV) and the Department for Business Innovation and Skills.

The results of the project were presented at the 2016 Niche Vehicle Symposium held at Williams F1. The CAE methodologies and optimisation routines developed for the project are now being exploited by our diverse customer base for the development of lightweight structures where minimal weight is an important design specification.

(2015) KTP with Warwick University. Understanding the lifetime performance of composites designed to operate in harsh environments

Our defence customers make extensive use of composite materials in their armour applications. These are high-stiffness and high-strength composite materials used to provide structural performance in lightweight structures. In addition to structural performance, protection against high-energy threats during ballistic impact and blast events is also a requirement.

Aside from the obvious weight-saving benefits of combining the structural and ballistic impact protection of composites in certain applications, possible downsides could be reduced strength of the structure post impact and reduced impact protection after a certain lifespan due to environmental factors and fatigue.

The focus of this R&D was the investigation of these factors under laboratory accelerated ageing tests, the two areas of primary interest being thermal ageing and fatigue ageing as it was believed that these areas may have the most significant effect on performance and are factors that cannot easily be protected against.

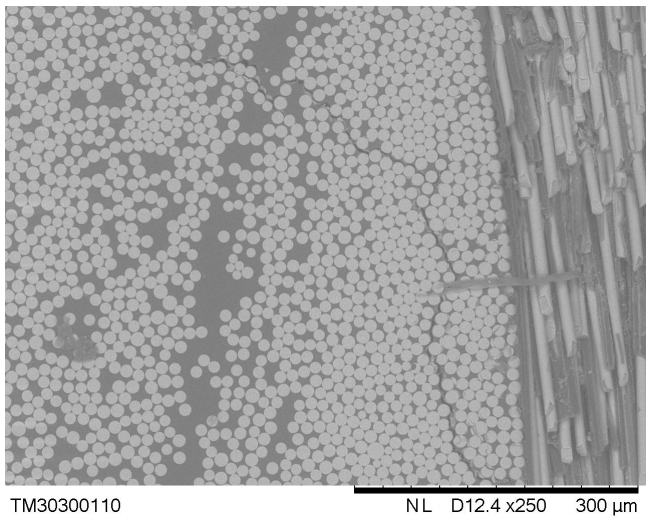

Testing was carried out at the University of Warwick and mechanical testing was carried out on a range of machines including DMTA, tensile, compression, charpy and fatigue. Samples were investigated for failure using a range of inspection technologies such as optical 3D microscopy, CT scanning and SEM.

Ballistic testing (V50) was carried out using a gas gun and a 1.1g chisel nosed FSP (Fragment Simulating Projectiles).

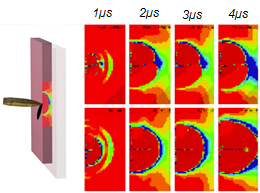

(2014) PASS2014 – The Effect of Bullet Yaw on the threat level; a numerical investigation

Our R&D dealt with the subject of bullet yaw and the effect that this can have on the penetrative power of armour piercing rounds and made use of some of the validated CAE models developed below. In the study, Simpact were able to replicate numerically the counter-intuitive phenomena found in experimental testing which is that a yawing round can have increased penetrative power. To investigate this effect experimentally is very difficult because the typical ballistic set up does not allow control over the yaw angle of the projectile. The results of this study are helping the interpretation of physical test results and ultimately can contribute to making the performance of armour systems more robust.

This work was presented at PASS2014 (University of Cambridge). Please see our Publications area for more information.

(2014) PACET (Pre Strain Analysis of Composites using Emerging Technologies)

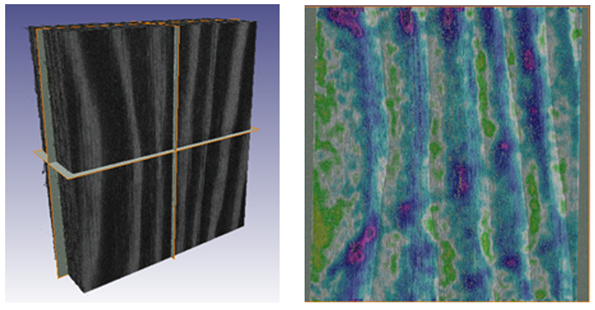

In 2014, Innovate UK awarded £1.25m in feasibility studies to bring emerging imaging technologies closer to commercial use. Simpact were one of 9 companies awarded funding and our project was carried out with academic partner University of Warwick. Led by Simpact, It investigated the extension of using digital volume correlation (DVC) in combination with images obtained by micro x-ray computed tomography to examine manufacturing strains within composite materials and strains within composites under loading.

Safety-critical composite components are frequently over-engineered with large safety factors as the strains introduced during manufacture are unknown and little is understood of the effect that these can have on the response of a structure to loading. Detailed analysis of material response is gained through FEA simulation and although some data can be obtained from experiments, this is typically quite limited.

With the successful completion of this project, Simpact are now able to gain a full internal strain analysis of composite samples. This involves the sequential scanning of samples at subsequent stages of manufacturing. Whilst a number of challenges still remain, strain data is now being used to correlate our FEA simulations and to identify where design improvements can be made. This is crucial in the development of composite structures where strains have a major role in the manufacturing process. This is particularly important for high value businesses that manufacture safety critical components and assemblies made from high strength composites.

(2014) Transforming the role of simulation in new product development

This was a major R&D project with partners University of Warwick and Morgan Advanced Materials and ran over two years with a total investment exceeding £1M.

The unique combination of Simpact's advanced modelling capabilities and the state-of-the-art metrology and visualisation facilities at the University of Warwick helped facilitate the outputs of the project. The project transformed the accuracy and communication of impact simulation, optimising transient models through correlation with real world geometric and high speed video data, and developed novel and innovative methods for visualising and interacting with simulation outputs.

This improved confidence and understanding in end users and provided Simpact and their customer base with the capability to model in detail the dynamic response (ballistic or blast) of ceramic armour systems. The project was a major achievement in maximising the value of CAE in the worldwide armour system community.

(2012) Inconsistency of threat level in soft armour standards, correlation of experimental tests to bullet X-ray 3D images

This R&D built on the original work done in 2011 (see below) and was carried out in partnership with the Metropolitan Police and the University of Warwick. The CT method was developed to apply the technique to correlate bullet impact response to jacket thickness variations. A set of 20 bullets was selected to analyse both intra and inter bullet variations using an image based analysis method to map the jacket thickness and measure the centre of gravity. Thickness variations of the order of 200µm were found commonly across all the bullets along the length and an angular variation of up to 50µm was found in a few bullets. The bullets were subsequently impacted against a rigid flat plate and re-scanned. The results of the experiments are shown and compared to the un-deformed bullet jacket thickness variations. The conclusions are relevant for future soft armour standards and provided important data for CAE model correlation and development.

The results of the work were presented at PASS2012 (Nuremburg) and published in ‘Forensics Science International’. Please see our Publications area for more information.

(2012) KTP with the University of Warwick. Developing a repeatable methodology for the optimisation of new products made from innovative sustainable materials.

With access to state-of the art materials test and characterisation facilities at Warwick, the project focussed on the non-linear FEA characterisation of three organic materials and composites which have strong potential for structural applications.

This included pumice, a naturally occurring lightweight structure that can be used as an impact energy absorber and SuperCoral, a bio-based high-impact resistance resin used as a prereg in a range of commercial composites made from carbon, glass, cellulose, and flax textiles with both UD or woven patterns.

The project resulted in non-linear material cards that can now be used for simulations (both the static and dynamic loadcases) of structures making use of these materials.

(2011) Inconsistency in 9mm bullets measured with non-destructive X-ray computed tomography

Armour systems are certified against standard threats and our R&D saw that there can be a significant dimensional variation within standard classes of projectiles. The objective of this project was to develop a method to accurately measure the in- and external dimensions of projectiles using x-ray technology. This allowed for statistical analysis and true representation in our predictive CAE models.

Being a joint collaborative R&D project with the University of Warwick and WMG (Warwick Manufacturing Group), the majority of the work was conducted by a researcher at the University as this is where the x-ray technology is housed.

The results of the project were published in ‘Forensics Science International’. Please see our Publications area for more information.

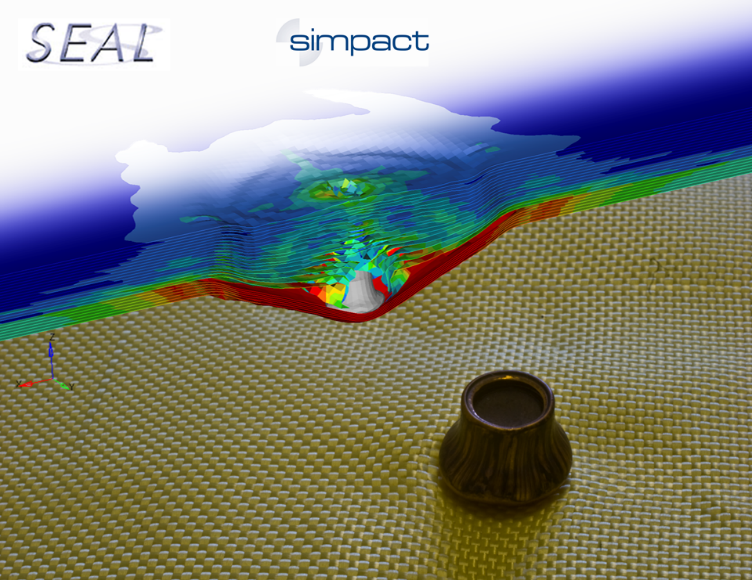

(2009) Multi layer dry fabric ballistic impact numerical analysis

Prior to this project, Simpact had been successful in demonstrating the performance of resinated aramid firing packs against Plastilina backing (as per the standard) where the woven aramid yarns are bonded together in a resin to create the sheets that make up a bullet resistant vest.

Our project partner, SEAL Spa (now SAATI Spa) had not experienced or made use of CAE and although the results generated from the previous work were both realistic and impressive, we needed to prove that our CAE models were valid for SEAL materials and for their set-up. For the development, Seal made use of a sysem where the layers of fabric are clamped in a frame (known as a v50 frame or target retention system). Also, the majority of SEAL materials used in personal protection applications are non-resinated where the yarns are able to ‘slip’.

This presented significant technical challenges from both a materials and modelling perspective. A planned programme of work included a visit to SEAL in Milan, Italy to carry out specific mechanical tests and conduct live firing range experiments. The results were collated and taken back to the UK where they were processed and used for making comparisons to our predictive CAE models. The Investment included new CPU solving and software capacity and the results of this project were presented to SEAL in Italy in July 2009.