Engineering Calculations

From hand calculations following basic engineering principles to finite element based simulations of complex multi-phase systems.

- Home

- CAE Capabilities

- Engineering Calculations

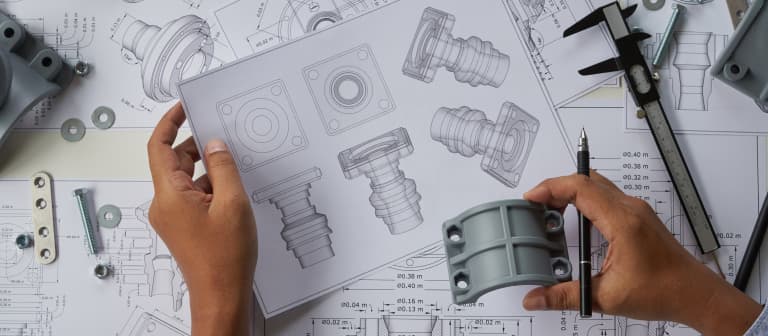

Hand Calculations

Mathematical processes performed by hand.

A core skill in engineering that is in particular valuable in the concept stage of a system design to find out the limits of what is possible. It is also good as a sanity check for complex numerical calculations.

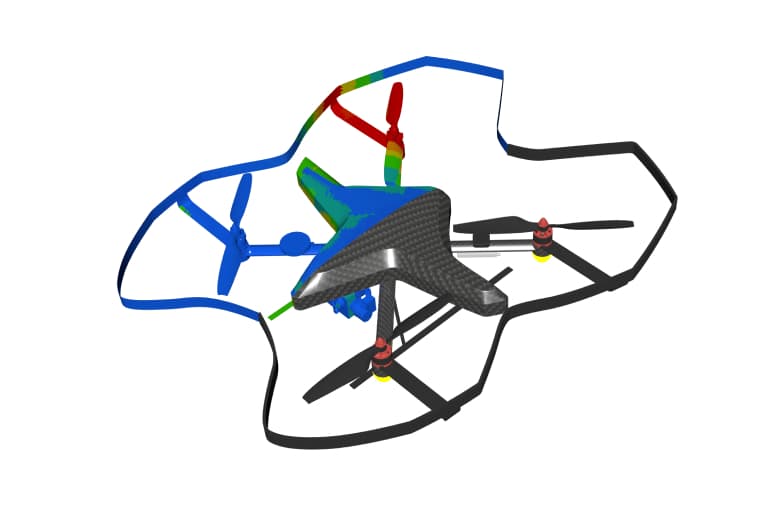

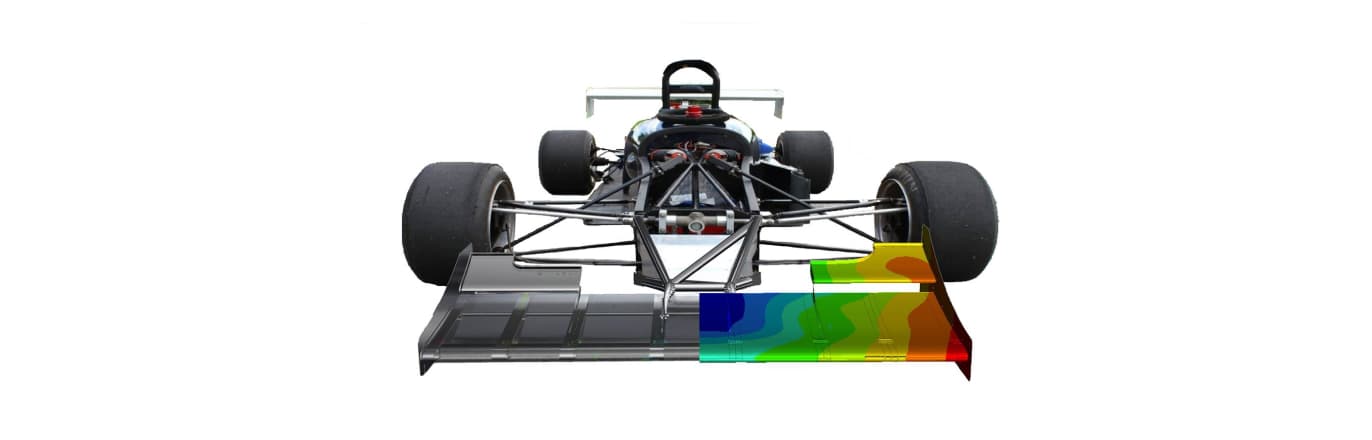

Numerical, FEA and SPH analysis

An essential CAE tool for new product design and development

Although most calculations can be carried on local computers on our secure intranet, we make use of remote systems when necessary.

HPC and Cloud Computing

The right computing capacity no matter the size of the job.

Although most calculations can be carried on local computers on our secure intranet, we make use of remote systems when necessary.

Want to find out more? Get in touch

Contact Simpact today to tell us about your project, and see how we can help.