Engineering Projects

We proudly present a selection of our projects, research projects and product development.

- Home

- Projects

Automotive

HPC for Vehicle Safety Simulation

High Performance Cluster computing making use of a dedicated independent service centre.

Read more

Rail & Marine

Spacetrain – Spaceframe Structures for Rail

Getting rid of dead weight in public transport.

Read more

Consumer

Bicycle Helmet Impact Development for EN1078 Drop Test Certification

Our customer was an Industrial Design Consultancy who were working closely with a new manufacturer of a range of road bicycle accessories.

Read more

Consumer

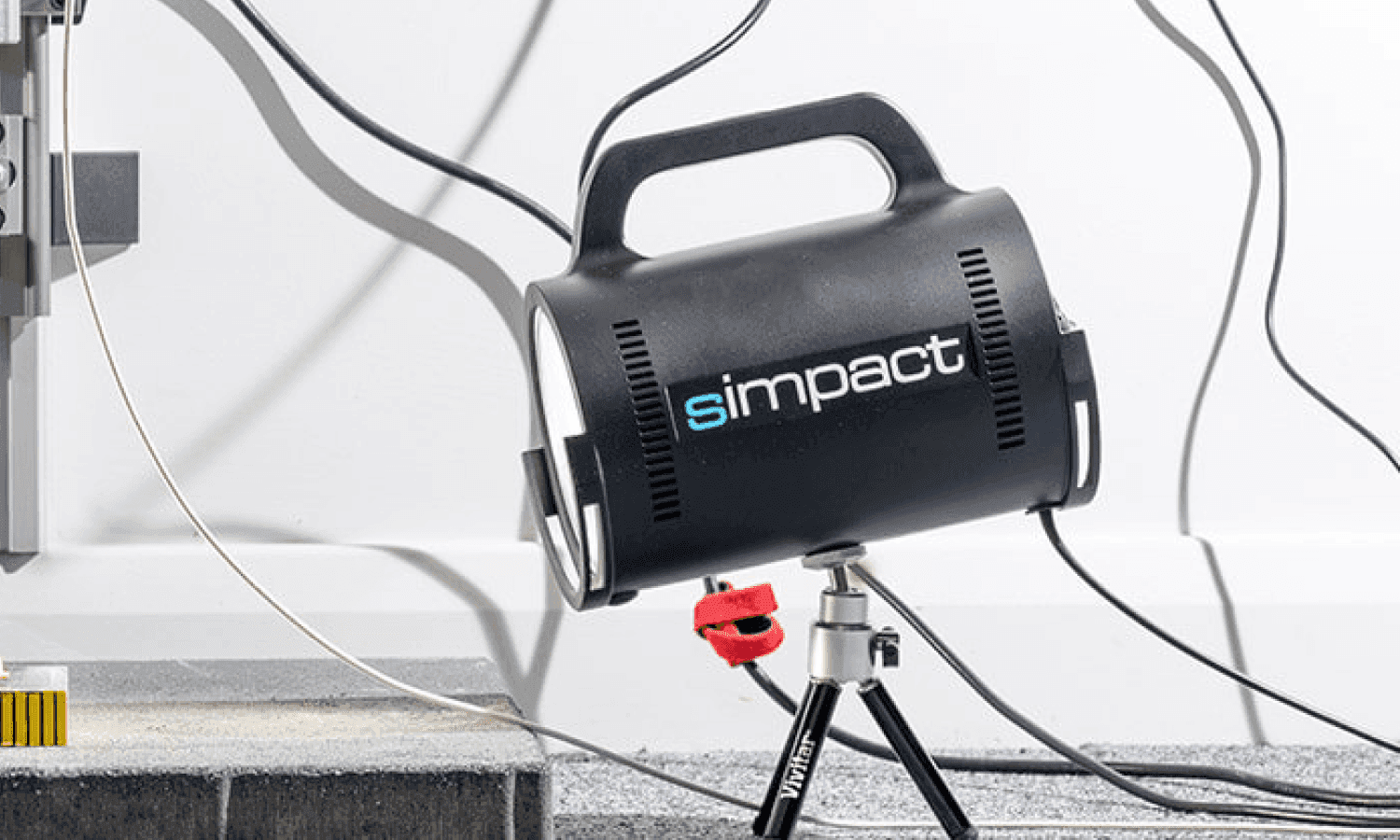

ICARUS

Innovative technology designed for high speed video and high end photography.

Read more

Industrial

Simpact/GCE Editorial

The design of a novel protective guard for a gas bottle valve. Traditionally these items are made out of steel, this is the first of a generation of polymer based designs.

Read more

Defence

Shaping the Future of Body Armour

The effectiveness of PPE is compromised by ergonomic issues hindering the wearer's mobility. This study describes what it takes to develop more ergonomic chest plates.

Read more

Defence

How soft armour works

Have you ever wondered how a bullet resistant jacket works and how the layers of fabric within stops a bullet? Simpact have, and by understanding fully how something works you are in a much better position to tailor a better solution towards a specific set of requirements. It makes the difference between a trial and error and a scientific approach.

Read more

Automotive

BLiSS - Butted Lightweight Steel Structures

The UK low volume/niche vehicle industry and the bicycle industry have been a particular interest of ours and in this project, we transfer technology from one to the other and evaluated the use of butted (variable wall thickness) tubing for lightweight automotive spaceframes.

Read more

Defence

The application of 3D Digital Image Correlation (DIC) to blast load cases

Our defence client came to us asking for us to provide an accurate calculation of dynamic displacements in 3D during a blast load case

Read more

Aerospace

Airbag Design For Aircraft Store Capture

Our customers seem to like working with us and we have been asked to write about what we do to make more people aware of the nature of what Simpact offer. We’d like to do this by talking about an interesting Aerospace project. Like most of our customer enquiries, it started with a phone call where we helped them to identify their requirements

Read more

Automotive

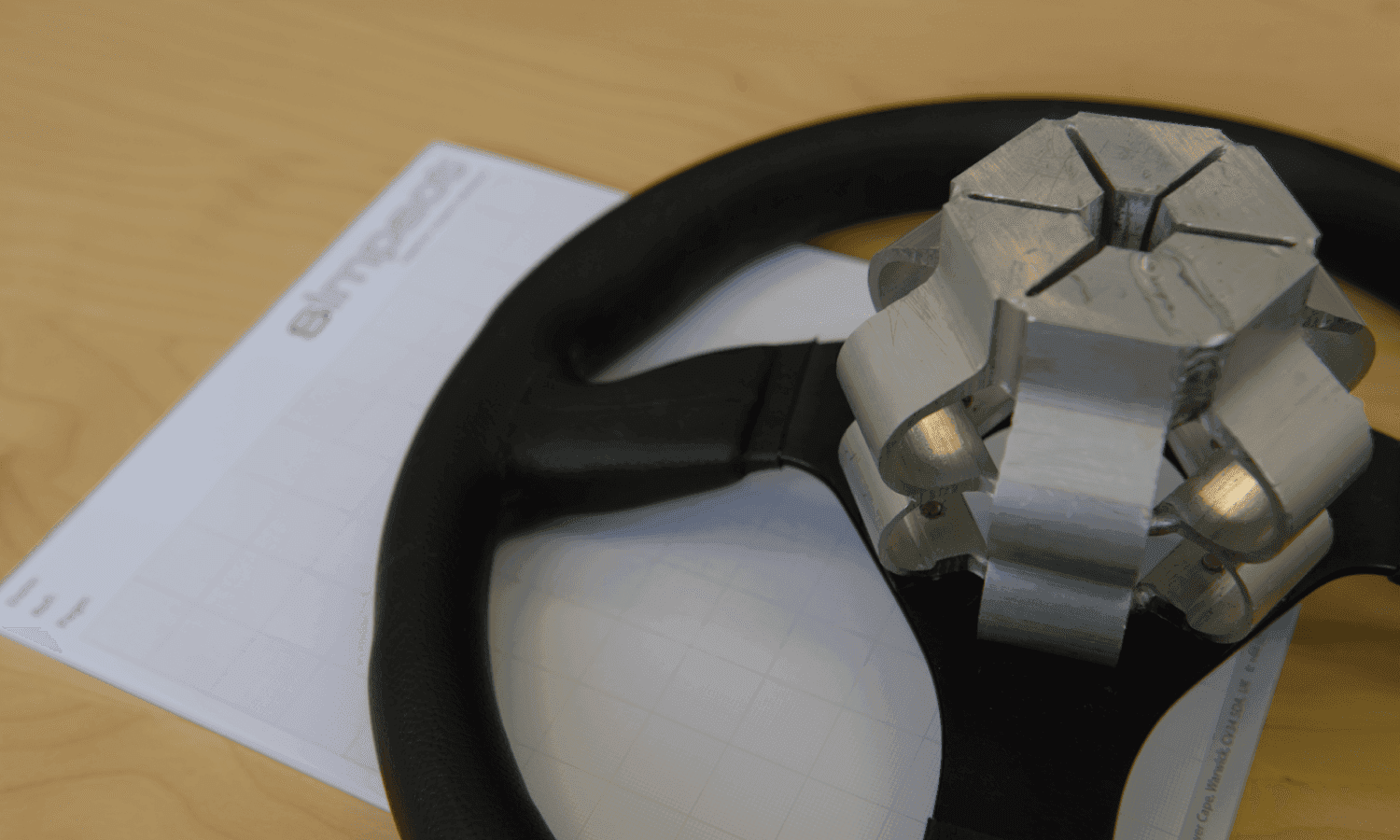

Impact Energy Absorbing Boss

The impact energy absorbing boss has been designed, developed and manufactured by Simpact for use by their Niche vehicle customers wanting to achieve ECE-R12 European Type Approval. The boss is retrofitted to an existing steering column assembly between the column and steering wheel.

Read more

Aerospace

High-flying technology for drone impacts

Application of cutting-edge Finite Element Analysis (FEA) to Unmanned Aerial Vehicles for safety and crash analysis

Read moreInterested in working with us? Get in touch to find out more

We would love to hear about your project, get in touch and let’s explore how the expert team at Simpact can take it from design target specification through to verification.

- 1

- 2