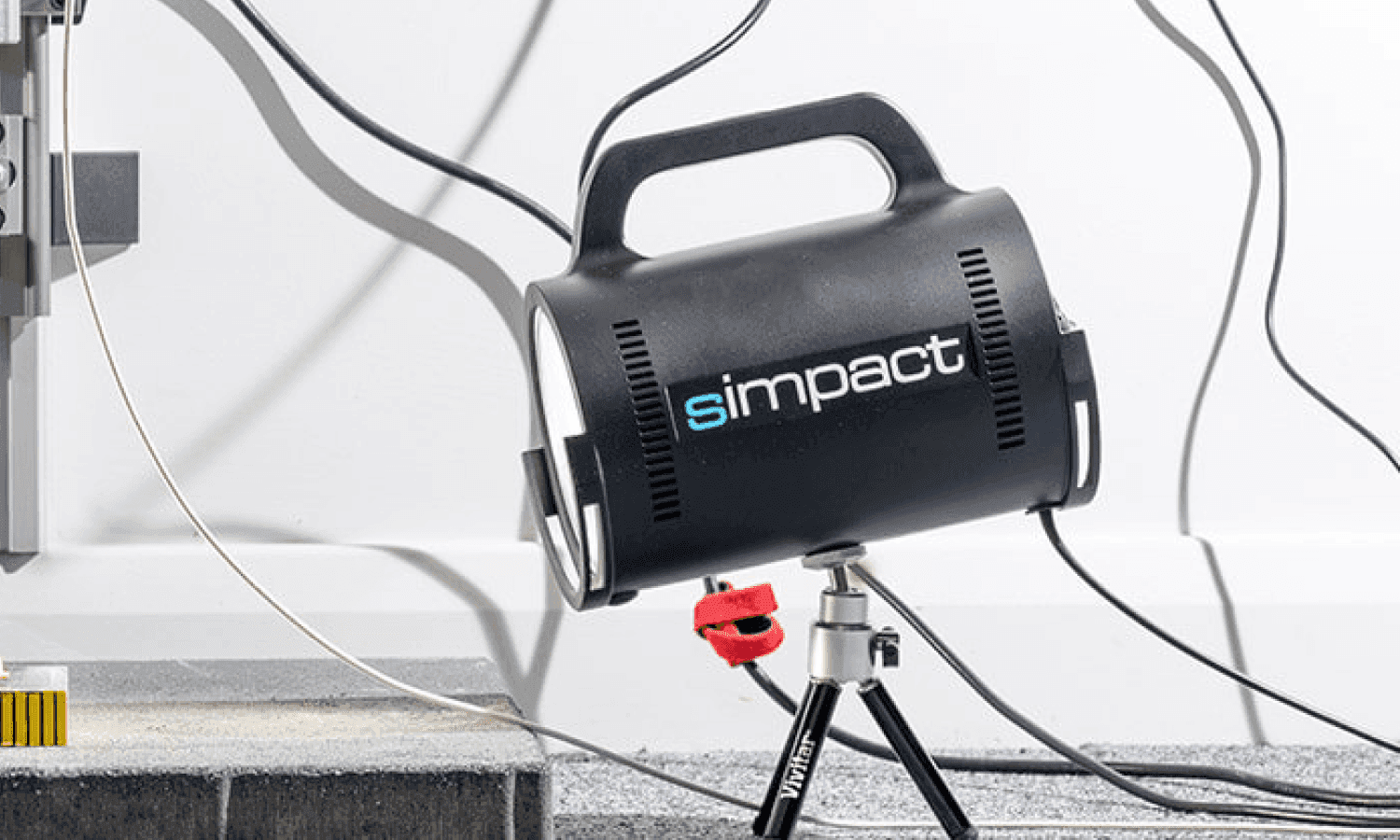

About Simpact

At the heart of Simpact lies a strong approachable team of trustworthy people that love engineering design. You are in safe hands with Simpact. We are an agile engineering consultancy with a core business activity in the design, development and engineering of bespoke structures. Our vast experience, across diverse markets allows us to solve the most demanding Engineering challenges.

- Home

- About Us

Safety, Mobility & Sustainability

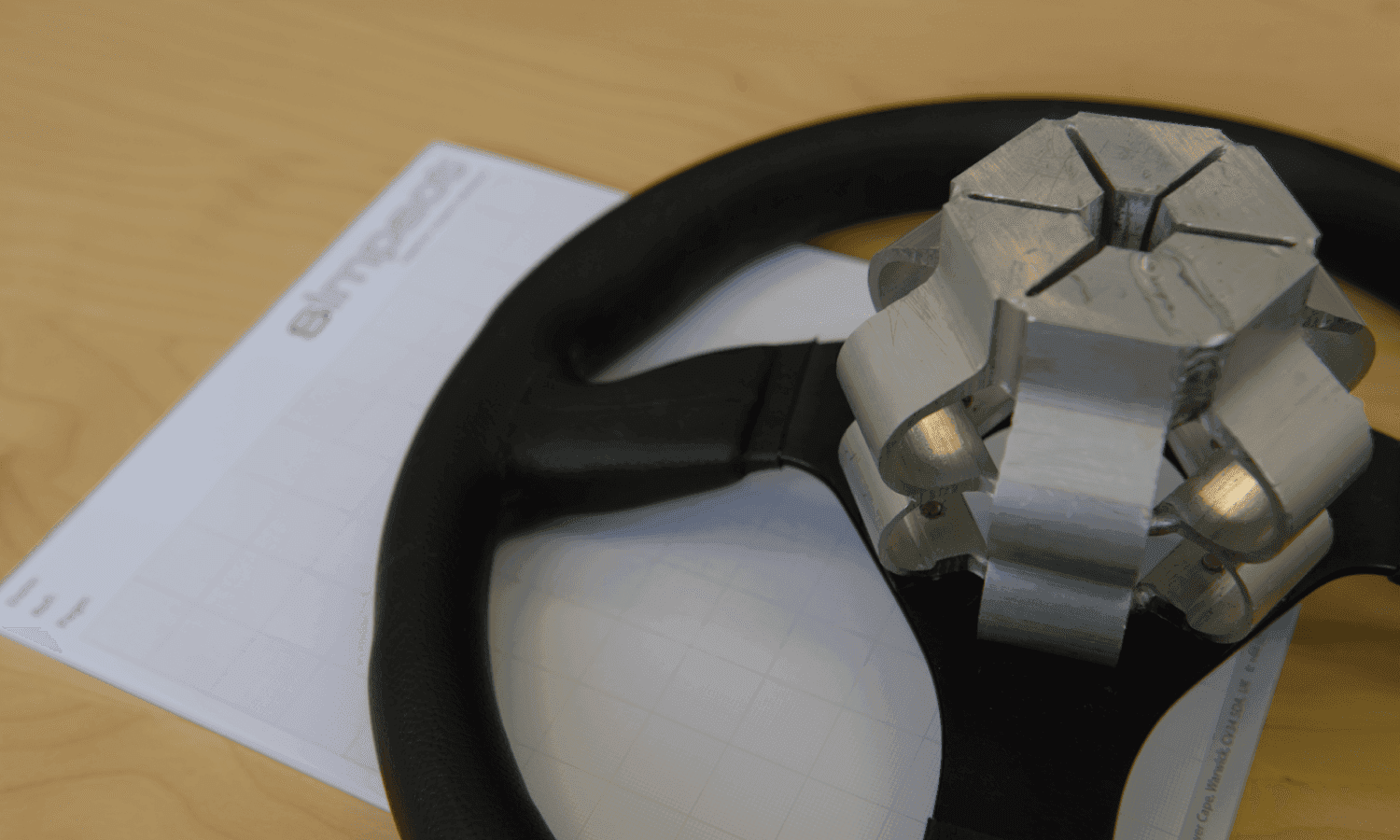

Founded in 2000 by Tim Williams and Dirk Landheer by putting the knowledge and expertise gained from their PhDs in automotive safety into practice, Simpact helped to shape the CAE revolution in automotive safety development and continuously pushed boundaries by applying innovative techniques.

In 2007 Simpact began to redefine itself by embarking on an active programme of diversification. The aim was to reduce reliance on the cyclic automotive market and seek out new markets that have not yet experienced the benefits of the CAE revolution. With our company cornerstones that incorporated a social ambition and a strong value base, Simpact broadened their market coverage to include project work in Defence, Aerospace, Industrial and Consumer.

Non-Stop Innovation

Today Simpact make full use of their vast experience, academic backgrounds and relationships to conduct cutting edge R&D and project work.

By continuing to work closely with the UK’s top Universities, Simpact has exclusive access to the latest techniques and state-of-the-art technology.

Safety has always been at the centre of everything we do. Some of our work saves lives, and as we grow and diversify, this is what continues to drive us.

View our Engineering ProjectsSome of our Engineering Projects

Key Stakeholders

We favour simple job titles at Simpact. We just say what we are best at, and our small but formidable international team of cherry-picked engineers do the rest.

Dirk Landheer

Managing Director

Dirk was born in Nuenen, a small Dutch village best known for the connection to the artist Vicent van Gogh.

Tim Williams

Business Development

Tim is edgy with his ideas and grew up on adrenaline and a need to go fast.

David Lemouton

CAE Specialist

David grew up in rural Normandy, France, and pursued a challenging five-year engineering curriculum.