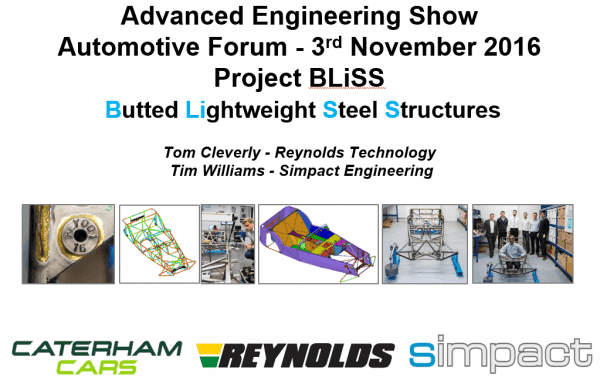

BLiSS (Butted Lightweight Innovative Steel Structures)

Last year our project consortia won R&D funding from the Niche Vehicle Network to investigate the feasibility of using butted tubing for low volume vehicle lightweighting. This year, we delivered the project and the world’s first spaceframe chassis using butted tubing technology. The BLiSS project was carried out alongside Reynolds Technology (pioneers of the original double-butted tubing set in 1898) and Caterham Cars. (manufacturer of the legendary 7 sports car)

As part of our dissemination series for the project, we will be presenting at this months Advanced Engineering Show at the NEC. The presentation is included in Forum 5, Automotive Engineering and will show how we used CAE to achieve a 10% reduction in chassis mass without effecting torsional/bending stiffness. Important for our customer and end user, Caterham was the challenge to deliver a design without any changes to packaging of the vehicle or the jigs used for manufacturing. Key to delivering these targets was the development of an accurate computer model of the 7 which was correlated to test within 3.3%

The Niche Vehicle Network will have a feature area in Hall 2 and will include one of the new prototype spaceframes. For the Niche Vehicle Network website, please visit www.nichevehiclenetwork.co.uk. For the Advanced Engineering website, please visit www.advancedengineeringuk.com

For the Reynolds Technology website, please visit www.rtl.cc. For the Caterham Cars website, please visit www.caterham.com

Written by

Dirk Landheer

Managing Director

Get in touch

Contact Simpact today to tell us about your project, and see how we can help.